Celebrating Sustainability: Non-Wood in Vanity Manufacturing

Every year, the furniture industry consumes millions of trees, with losing 18.7 million acres of forest every year, contributing significantly to deforestation and environmental degradation. This consumption not only threatens biodiversity but also exacerbates climate change. The furniture industry plays a significant role in driving this deforestation. Tropical hardwoods are highly sought after for their durability and aesthetics, leading to extensive logging in regions like the Amazon rainforest. This deforestation not only destroys vital habitats for countless plant and animal species but also exacerbates climate change by releasing massive amounts of carbon dioxide into the atmosphere as mentioned in From Forests to Factories - Understanding the Alarming Statistics Behind Furniture's Environmental and Human Harm. As we celebrate the annual Tree Planting Festival, it's time to reflect on our practices and explore sustainable alternatives to wood in furniture manufacturing.

The Environmental Impact of Furniture Manufacturing

The furniture manufacturing industry, traditionally reliant on wood as a primary resource, plays a significant role in environmental degradation. This impact extends beyond the simple act of cutting down trees; it encompasses a wide range of ecological consequences that warrant a closer examination.

Deforestation and Habitat Loss

One of the most immediate effects of wood-based furniture manufacturing is deforestation. As forests are cleared to meet the demand for wood, critical habitats for countless species are destroyed, leading to a loss of biodiversity. This not only affects the animals and plants that call these forests home but also disrupts ecosystems that provide essential services to the planet, such as carbon sequestration and water cycle regulation.

Soil Erosion and Water Cycle Disruption

The removal of trees for furniture production also leads to soil erosion. Trees play a crucial role in holding soil in place and maintaining its fertility. Without this natural barrier, soil is more susceptible to being washed away by rain, which can lead to poorer soil quality and increased sediment in water bodies. Additionally, forests are vital components of the global water cycle, and their depletion can disrupt precipitation patterns, leading to water shortages and affecting agricultural productivity.

Increased Carbon Emissions

Forests act as carbon sinks, absorbing carbon dioxide from the atmosphere and mitigating the effects of climate change. The process of deforestation for wood production releases stored carbon back into the atmosphere, significantly contributing to greenhouse gas emissions. Moreover, the energy-intensive nature of furniture manufacturing processes, including transportation, processing, and finishing, further amplifies the industry's carbon footprint.

Overexploitation of Resources

The furniture industry's demand for specific types of wood often leads to the overexploitation of certain species. This not only threatens these species with depletion but also encourages the use of monoculture plantations to meet demand, which can be less biodiverse and more susceptible to diseases and pests than natural forests. The overreliance on a narrow range of species undermines the health and resilience of forest ecosystems.

The Growth Time of Trees Used in the Furniture Industry

The reliance on wood as a primary material in furniture manufacturing poses significant sustainability challenges, largely due to the lengthy growth times required for trees to reach maturity. Different species of trees, often favored for their strength, durability, and aesthetic appeal in furniture making, have varying growth rates, which can impact the sustainability of wood sourcing practices.

Hardwoods: A Slow Journey to Maturity

Hardwoods such as oak, mahogany, and teak, which are widely used in the furniture industry for their desirable properties, typically take decades to mature. For instance, an oak tree, prized for its hardness and grain texture, can take anywhere from 20 to 30 years to reach a size suitable for commercial use. More exotic species like mahogany and teak can take even longer, with growth times spanning 50 to 100 years before they are ready for harvest.

Softwoods: Faster Growth, Yet Not Without Concerns

On the other hand, softwoods like pine and cedar, also commonly used in furniture, tend to grow more quickly than hardwoods. Some species can be ready for harvest within 10 to 20 years. However, the faster growth rates of softwoods do not entirely mitigate the environmental impacts of deforestation and habitat loss. The demand for quick-growing species can lead to monoculture plantations, which lack the biodiversity of natural forests and are more susceptible to pests and diseases.

Celebrating Through Change: The Appeal for Sustainable Alternatives in Bathroom Vanity Manufacturing

As we delve into the heart of sustainable practices, the spotlight shines brightly on the realm of bathroom vanities, a staple in every home that presents a unique opportunity for environmental stewardship. The shift towards sustainable materials in bathroom vanity production not only addresses pressing environmental concerns but also sets a new standard for design and functionality in the industry.

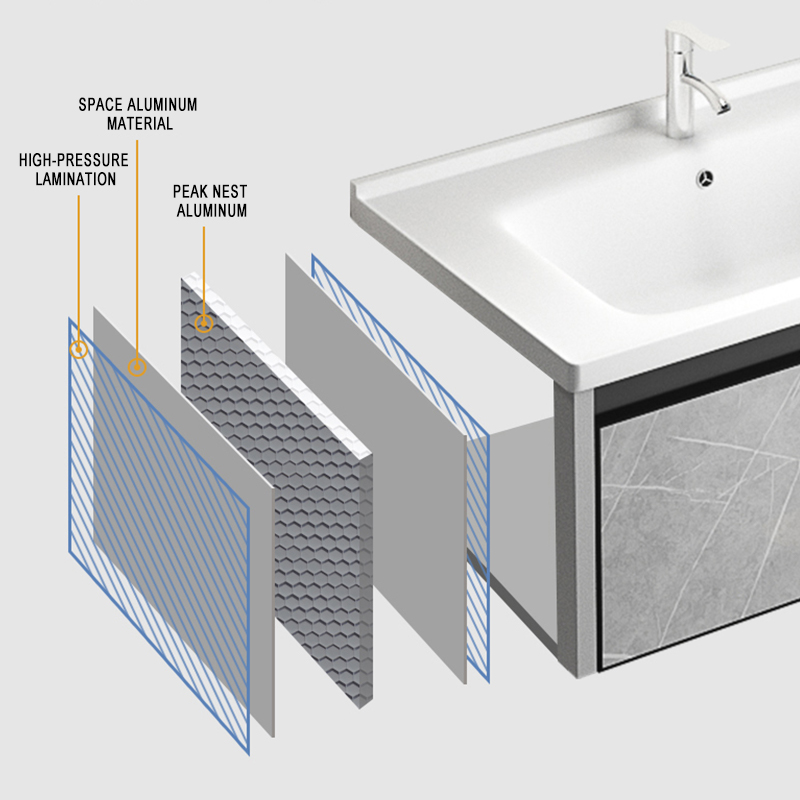

Aluminum: The Fusion of Lightweight Strength and Eco-Friendliness

Aluminum stands out for its exceptional combination of lightweight strength, corrosion resistance, and sustainability, making it an ideal choice for bathroom vanity frames and components. Its natural resistance to moisture and corrosion ensures longevity and durability in the humid environment of a bathroom, minimizing the need for replacements and reducing waste. Furthermore, aluminum's recyclability is a key environmental benefit; it can be recycled indefinitely without losing its properties, significantly lowering its carbon footprint. The energy required to recycle aluminum is merely a fraction of that needed for its initial production, fostering a cycle of sustainability that aligns with eco-conscious manufacturing practices. Design-wise, aluminum offers a sleek, modern aesthetic that can be easily adapted to various design trends, from minimalistic to industrial chic, providing versatility in bathroom vanity design.

Sintered Stone: Durable, Eco-Friendly Elegance

Sintered stone emerges as a revolutionary material in bathroom vanity design, offering unmatched durability and eco-friendly attributes. Created through the process of sintering—where natural minerals are fused under intense heat and pressure—it boasts a non-porous surface that is resistant to scratches, stains, and water damage. This makes it an excellent choice for vanity countertops, where durability and ease of maintenance are paramount. Its environmental impact is notably low, as the process utilizes natural materials without depleting resources or causing significant harm to ecosystems. Aesthetically, sintered stone provides a wealth of design possibilities, able to replicate the appearance of natural stone, wood, and other textures, thereby offering beauty and sustainability in one package.

Stainless Steel: Timeless Elegance with a Sustainable Edge

Stainless steel, known for its timeless elegance and robustness, offers a sustainable and durable option for bathroom vanities. Its inherent resistance to rust, stains, and corrosion makes it ideal for the bathroom's wet conditions, promising a long lifespan and reducing the need for frequent replacements. Like aluminum, stainless steel is 100% recyclable, with the majority of new stainless steel containing significant amounts of recycled material. This circular lifecycle minimizes environmental impact, conserving resources, and reducing landfill waste. Stainless steel's sleek and reflective surface adds a contemporary edge to vanity designs, complementing a wide range of bathroom aesthetics from modern to traditional. Its hygienic properties, due to its non-porous surface, further reinforce its suitability for bathroom environments, ensuring cleanliness and ease of maintenance.

Leading by Example: Our Commitment to Sustainability This Arbor Day and Beyond

As we observe Arbor Day today, our commitment to environmental stewardship and sustainable manufacturing practices is more pronounced than ever. At Hermitship Home, we've made a deliberate choice to move away from wood in our bathroom vanity production, embracing instead the innovative and eco-friendly possibilities of aluminum, sintered stone, and stainless steel. This decision underscores our dedication to not just reducing our environmental footprint but also leading the industry towards a greener future.

To Our Customers: Your Choice Matters

We invite our customers to join us in this The Ultimate Guide to Choosing the Right Materials for Your Bathroom Cabinet Business journey towards sustainability. By choosing bathroom vanities made from aluminum, sintered stone, and stainless steel, you're not only opting for high-quality and aesthetically pleasing products but also contributing to a more sustainable and responsible consumption pattern. Your support enables us to continue innovating and expanding our range of eco-friendly products, making a positive impact on the planet one vanity at a time.

As we commemorate Arbor Day, let's remember that our actions today lay the foundation for tomorrow's world. At Hermitship Home, we are proud to lead by example, championing the use of sustainable materials in our bathroom vanities. We believe that together, through conscious choices and collaborative efforts, we can achieve a balance between innovation, aesthetics, and environmental preservation. Join us in making sustainability not just a choice but a legacy for generations to come.